Wheel loaders 5065e - The emission-free wheel loader

The electrically-driven wheel loader 5065e is equipped with a 96-Volt lithium ion battery, which enables a running time of up to 4 hours without interim charging. The wheel loader also has compact dimensions, as well as a stacking payload of 1,750 kilograms. With the fully electric wheel loader 5065e, CO2 restrictions, soot particle limit values or noise emissions values to be met will no longer play a role in your daily work. The 5065e works locally emission-free, thereby protecting the environment and the user, and scores points in matters of efficiency and economy.

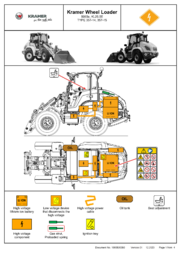

Wheel loaders 5065e

Benefits at a glance

- Battery technology: Powerful 96 V lithium-ion battery with a capacity of 37.5 kWh

- Exhaust emissions: No local exhaust emissions and clearly reduced noise level

- Loading: An integrated on-board charger with up to 9 kW enable fast loading

- Bucket tipping load: Compact dimensions with a bucket tipping load of 2,800 kilograms

- Operating costs: Lower maintenance costs compared with conventional diesel drive systems

Highlights

Lithium-ion battery

- Large capacity with compact dimensions and low weight enable long running times.

- Monitoring of all vehicle parameters and communication between electrical components through the integrated battery management system (BMS).

- Optimal operating temperature and maximum transmission range of the machine even in the cold season due to battery heater.

Flexible charging options

- Different charging plugs allow different power sources to be used for charging.

- Automatic regulation of the maximum permissible charging power by detecting the charging plug as well as the mains voltage.

- Type 2 standard installed on the vehicle enables the use of commercially available wall boxes and public charging points.

Easy charging process

- The charging point is easily accessible and protected by a flap on the outside of the vehicle.

- An additional display at the charging point makes it easy to read the battery status from the outside.

- Activation of the charging process and locking of the charging plug is done via a button or a lockable key switch.

Fast charging

- The integrated onboard battery charger enables fast charging of the battery.

- There is no need to carry an additional, external battery charger with the machine.

- Intermediate charging of the battery is possible at any time. This can maximize the running time of the machine throughout the working day.

Efficient electric drive

- Two separate electric motors for drive system and work hydraulics ensure maximum efficiency.

- The drive system motor is directly connected to the drive shafts and axles via a transmission, and the high torque ensures that the machine responds quickly.

- The electric motor for the work hydraulics is controlled according to demand, so the right quantity of oil is always available.

Further Highlights

-

Please note that the product range may vary depending on the country.

-

The technical data of the products may vary accordingly with the selection of different options.